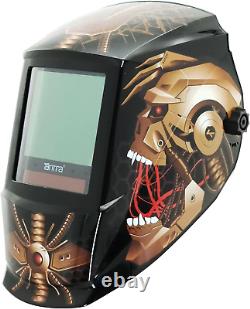

Antra True Color Auto Darkening Welding Helmet Large Window 13.5 Sqi, Wide Var

Instantly adjusts to the preset shade level as soon as the arc is struck, preventing eye strain and enhancing your welding accuracy. High-definition true color optics ensure a crystal-clear view of your workpiece, allowing you to maintain precise control and weld quality. Customizable headgear and ergonomic design provide a comfortable fit for hours of fatigue-free welding, ensuring maximum productivity. Tailor the helmet's response to your specific welding needs, adapting to various welding techniques and environments. Suitable for various welding processes, including MIG, TIG, Stick/MMA, Plasma and more, making it an essential tool for both professionals and enthusiasts.

More covering area, better viewing angle, more flexible. Luxury viewing size of 13.5 SQI provides comfort working zone, which is twice larger when compared to entry level lens. Easier to see awkward spots than smaller viewing size helmets, more flexible to be used in different scenarios. Clearer Lens with Blue Lights Suppression.

Clearer welding puddles and pools, more sensitive and 4 premium sensors. Blue light reduction lens (Optical Class 1/1/1/2) provides clear viewing and blue light protection, and helps to lay solid beads. 4 Redundant sensors ensures high reliability and durability. Quicker response time and more flexible when used in applications with partially blocked view. Versatility is another great asset of AH7-860 in addition to its reliable performance.

This unit is working on most of ARC related applications including but not limited to. Gas Tungsten Arc Welding (GTAW). , sometimes referred to by its sub-types M. Flux shielded arc welding (stick welding). Note: Different settings may be required for each application.

Antra's Interference Suppression Technologies enables AH7-860 to. Detects and response consistently on DC welding arc as low as. Minimize false triggering in industrial Metal-halide lights, on higher sensitivity setting if not facing lights directly. Minimize false triggering in sun lights, on higher sensitivity if not facing sun directly. As a rule of thumb, start with a shade that is too dark to see the weld zone.Then, go to a lighter shade which gives a sufficient view of the weld zone without going below the minimum. Set the switch to Grind, the lens will stay on shade 4, will not be activated by any arc. WARNING: Switch "Weld" mode to avoid accidental flashes.

First set the SHADE RANGE using the range selector switch, "5-9" or "9-13", then use the Shade dial to set the desired shade numbers. 5-8 is great for some low amp application and small current plasma cutting jobs. Dark to Clear Delay, to avoid glow flashes from the hot bead. Turn clockwise, the delay time will be increased. Controls how sensitive the sensors are responding to welding arc.

Proper setting can avoid false triggering from adjacent arc while ensures auto darkening when needed. Turn clockwise, the sensitivity will be increased. Set the sensitivity highest, and decrease if there false triggering exists.

All internal settings is great for people who need to work in limited spaces.